In recent years, China's offshore wind power industry has developed rapidly, with increasing installed capacity of offshore wind power. Offshore wind power piles have shown characteristics of ultra long, ultra large, overweight, and high-precision construction. At present, the heaviest offshore wind power piles have reached over 2000 tons, and the construction verticality requirement is within 0.3%. With the rapid development of wind power technology, offshore wind power has become a focus of attention for the development of renewable energy worldwide.

The Datang Hainan Danzhou Offshore Wind Power Project, a key energy engineering project in Hainan Province, is located in the Beibu Gulf in the northwest of Danzhou City, with an offshore distance of approximately 34 kilometers and a total installed capacity of 120 kilowatts. Recently, all construction of the project has been successfully completed and the first offshore green power in Hainan has been successfully connected to the grid.

Innovative solution for offshore wind power pile construction

At present, the main function of offshore wind power pile construction platforms is to work on construction piles. It uses four auxiliary piles to locate the construction platform, so that the construction platform can remain stable under the attack of offshore wind and waves. The main equipment for driving and pulling platform auxiliary piles is the vibrating pile hammer.

It is a great honor that for the Datang Hainan Danzhou offshore wind farm project, CCCC First Harbor Engineering Co., Ltd. has used our company's ultra large EP1600 resonance free vibration hammer to complete the auxiliary pile driving and pulling work.

Let's take a look at why the EP1600 resonance free vibration hammer can drive and pull out piles so quickly and smoothly?

What are its advantages?

Technology and advantages

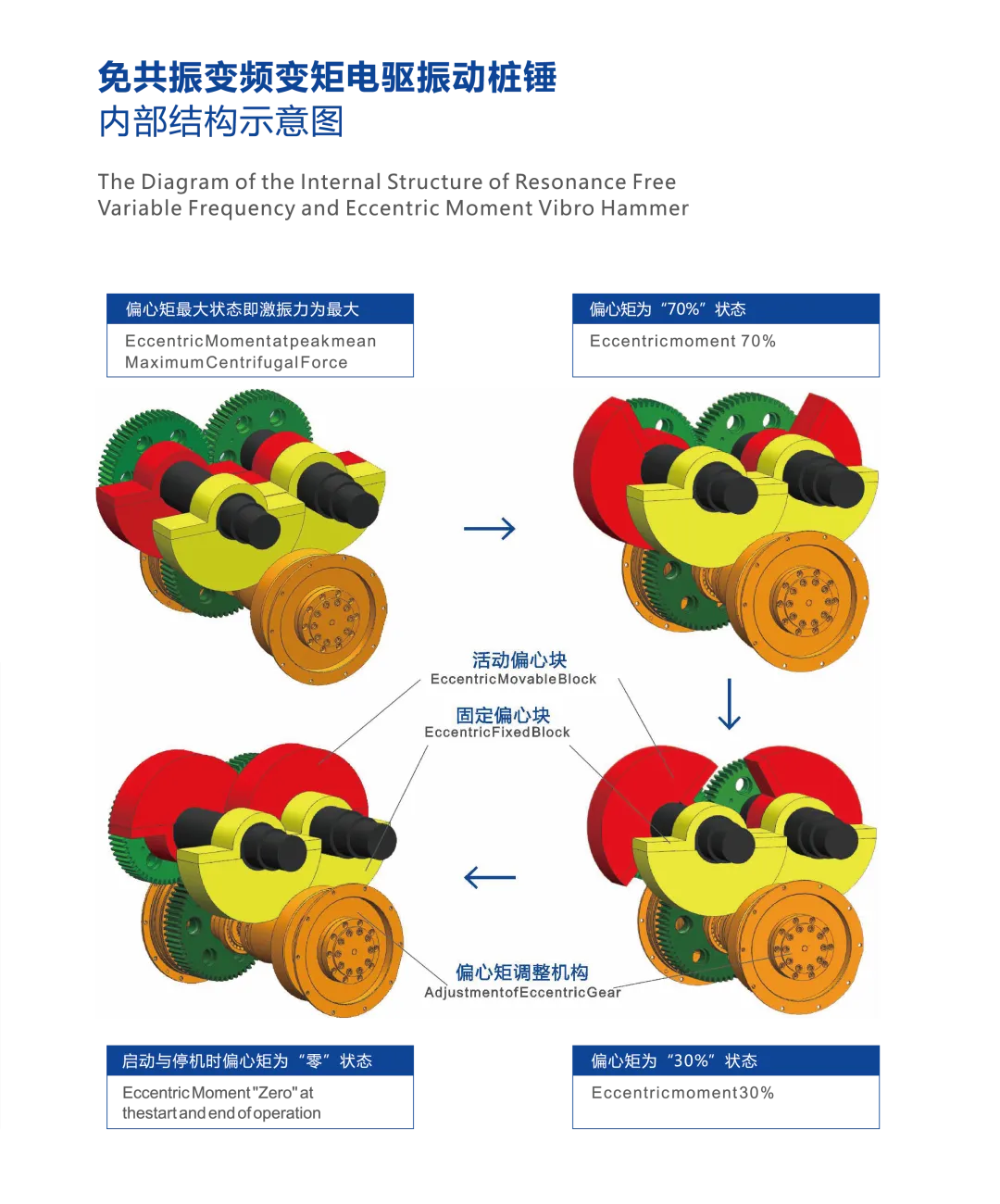

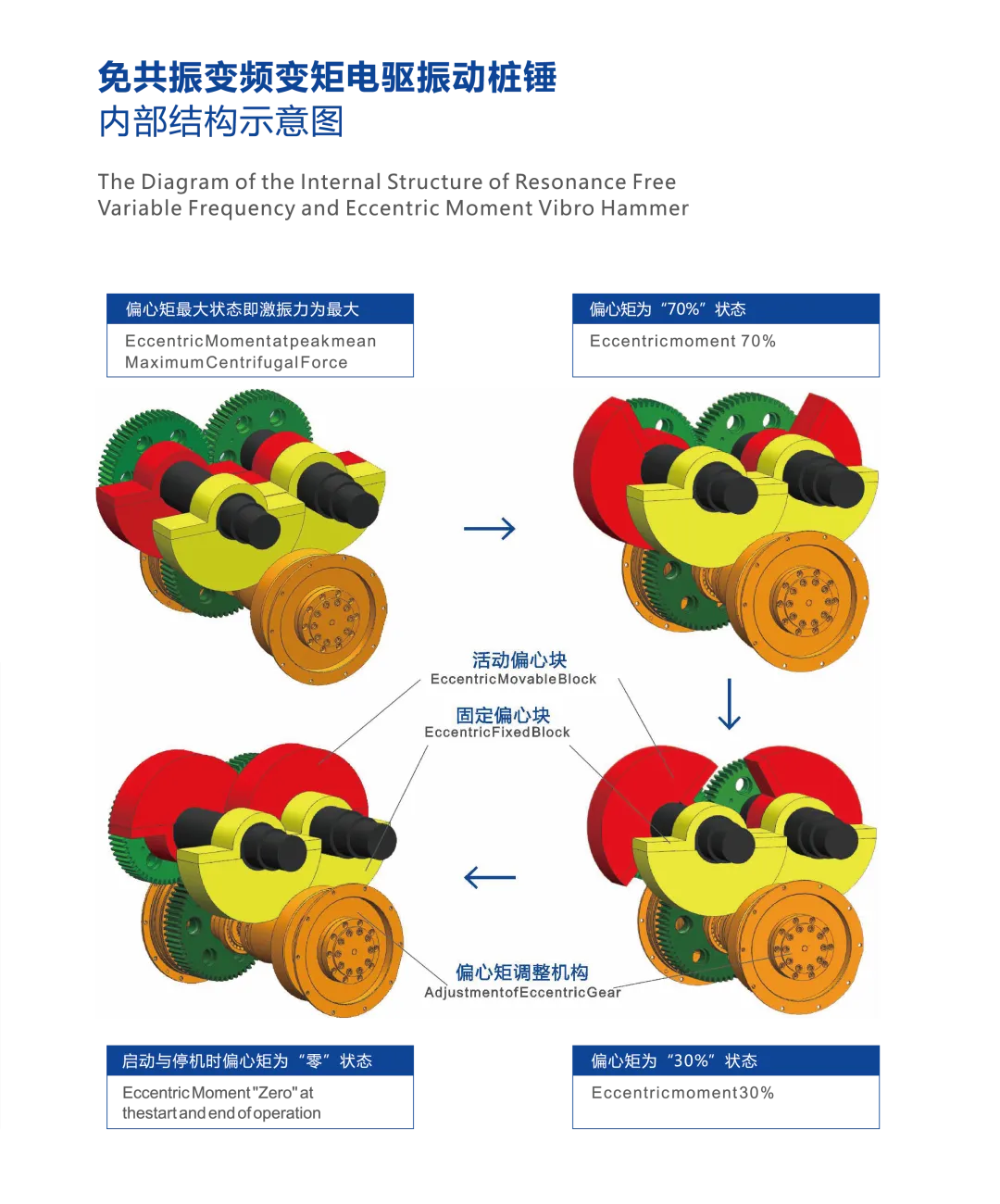

The biggest feature of the EP series vibration hammer is the use of a hydraulic control eccentric torque conversion device, which can achieve "zero" start, "zero" stop, and infinitely adjust the eccentric torque from zero to the design maximum value during operation. Compared with traditional vibration hammers, large resonance free vibration hammers have shown great advantages: energy saving, safety, environmental protection, and economy. At present, the mainstream vibration hammers on the market are electrically driven, often using industrial electricity or generator sets as power sources. This machine can be started under zero eccentric torque conditions, that is, no-load starting, solving the problem of requiring a large capacity power supply for traditional vibration hammers to start with eccentric torque. Zero start and zero stop can enable the vibration hammer to start and stop without vibration. After crossing the resonance frequency zone, the eccentric torque can be adjusted to the working condition, thus avoiding the resonance that inevitably occurs during the traditional vibration hammer with eccentric torque starting and stopping process, and preventing resonance from damaging equipment and affecting construction safety. The eccentric torque of the EP hammer is infinitely adjustable, and can be adjusted to "zero" before starting and stopping, allowing the vibrating hammer to start and stop under "zero" excitation force. Therefore, only a small power supply is required, reducing the number of supporting equipment. At the same time, reducing energy consumption and truly achieving "energy-saving and cost saving".

The advantages of continuously adjustable eccentric torque technology in terms of efficiency:

A major problem faced in the construction of pile driving is the uncertainty and diversity of geological conditions, and the construction efficiency is greatly affected by changes in geological conditions. The EP series vibration hammer can infinitely adjust the eccentric torque during machine operation. The amplitude can be infinitely adjusted from "0-Max" or "Max-0". By cooperating with sensors and equipped with a visual display module for eccentric torque adjustment, the eccentric torque can be visualized and adjusted accurately. Real time monitoring and adjustment of performance parameters such as eccentric torque and amplitude during machine operation can be achieved to meet the requirements of different geological conditions for pile sinking and extraction, thus achieving ideal pile sinking and extraction speed and efficiency.

The machine adopts a variable frequency and vibration resistant dual output shaft motor with independent intellectual property rights; A dedicated variable frequency vibration resistant motor with stronger temperature and overload resistance compared to traditional vibration resistant motors, longer service life, and wider adaptability. The motor adopts a dual output shaft structure, with uniform force distribution, which can reduce bearing pressure, lower temperature rise, and is more conducive to long-term operation.

The overall structure of the machine adopts a horizontal structure. The advantages of this structure are: low center of gravity, making the operation smoother, safer, and with low work noise; More conducive to heat dissipation and lubrication, with low temperature rise, able to meet long-term continuous operation.

The machine adopts a shock absorber with a beam independent structure, which reduces the overall height of the machine, makes maintenance and disassembly simple, and facilitates transportation.

Project effectiveness

The EP1600 resonance free vibration hammer has provided strong construction efficiency assurance for the owner in the Datang Hainan Danzhou offshore wind power project, and has received high praise and recognition from the owner.

The EP series resonance free vibration hammer is not only "safe", "energy-saving", and "environmentally friendly", but also "efficient" and "stable", making it a powerful tool for offshore wind power pile foundation construction in the new era.